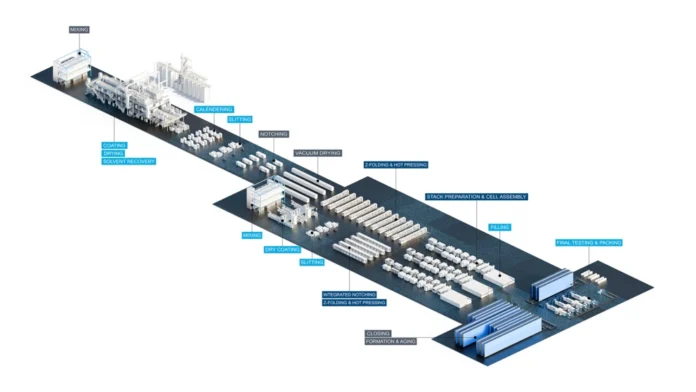

Dürr and GROB have announced a new lithium-ion battery cell concept factory. The system targets the EV segment, featuring dry electrode coating and an advanced Z-folder cell assembly with integrated notching.

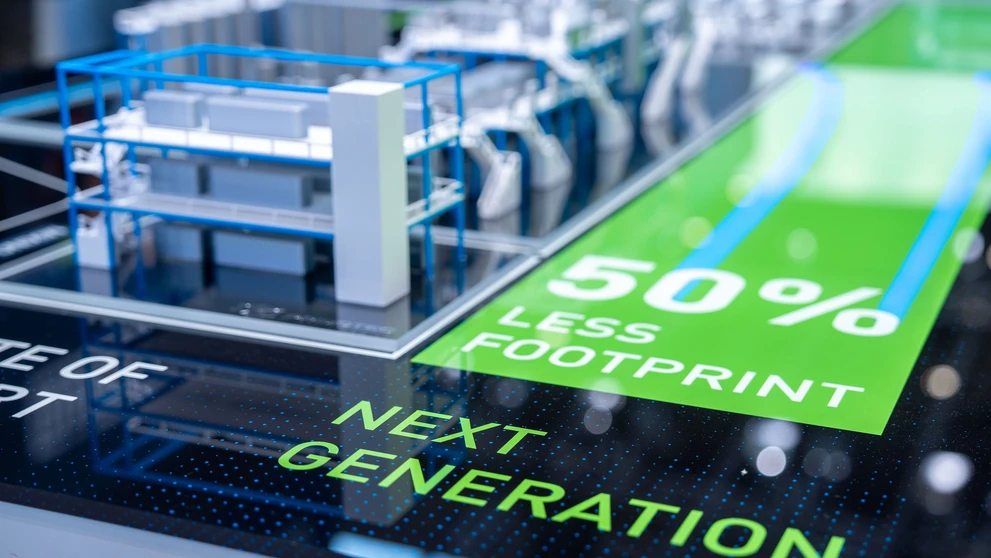

According to Dürr, the concept factory reduces production space requirements by 50 percent and cuts energy consumption by 70 percent compared to traditional methods. Key technologies include dry coating of electrodes—specifically, Dürr’s X.Cellify DC family, which uses a dry-mixed active material pressed into a free-standing film via calender machines. This process employs the Activated Dry Electrode technology from LiCAP Technologies, eliminating the need for a drying process and solvent recovery. Excess film material can be fully returned to production before lamination, reducing waste.

The dry coating proof of concept has demonstrated consistent quality and is scalable, with a proof-of-concept plant operating in a dry room at Ingecal in southern France. Dürr is now seeking pilot partners among industry players for gigawatt-scale projects.

Meanwhile, GROB’s new generation Z-folder for cell assembly integrates notching, achieving 95 percent system availability and further increasing throughput while minimizing space needs. The separator is precisely handled with low web tension, which improves reliability.

In addition to electrode processing, Dürr reports a new method for electrolyte filling of battery cells, where electrolyte is added at up to 30 bar—two to three times higher than standard industry pressures—enabling more precise dosing and faster filling. For the classic wet coating process, Dürr has also enhanced automation and process control. Sensors provide 0.5 micrometer accuracy in calendering, and laser dryers deliver a 50 percent increase in web speed.

Digital tools are also integral, as Dürr and GROB offer digital mapping and simulation of the factory, supporting production planning and quality analysis through manufacturing execution system/manufacturing operations management (MES/MOM) software from Dürr’s iTAC subsidiary.

“With our expanded portfolio of highly available machines and systems, we jointly cover almost the entire value chain for battery cell production with our own technologies,” said German Wankmiller, CEO of the GROB Group.

Dürr is consolidating its electrode coating and electrolyte filling products under the new X.Cellify platform.

Source: Dürr